Softgel manufacturers are familiar with the difficulties associated with cleaning gelatin build-up, plasticizers, oils and pigments.

Removing these tough residues from stainless steel equipment poses a significant challenge in turnaround times and operational efficiencies. Conventional cleaning techniques like traditional wipes and standard detergents often fail to tackle heat-cured or sticky contaminants effectively.

To overcome these hurdles, we present the Sahara+ Cleaning System. a validated multi-stage process designed to dismantle stubborn residues and return critical equipment surfaces to GMP standards.

The Cleaning Challenge in Softgel Production

Softgel processing equipment is routinely exposed to a variety of stubborn residues:

- Heat-dried gelatin films: Hardened layers that bond tightly to surfaces

- Sticky plasticisers: Compounds like glycerin and sorbitol that resist standard cleaning

- Oily residues: Coatings from medium-chain triglycerides (MCT) or mineral oils

- Pigmented residues and APIs: Colourants and active pharmaceutical ingredients that can stain equipment

These contaminants strongly adhere to contact surfaces, often resisting conventional wipe-downs and leaving behind streaks or particles that compromise cleanliness and batch consistency.

The Sahara+ Cleaning System: A Three-Step Approach

The Sahara+ Cleaning System provides a structured method that leverages three specialised tools to deliver exceptional results:

Step 1: Break Down Residues with Sahara Scrubbing Foam

Product: Sahara Foam scrubbing sponges or Foam Heads (for mops or tools)

Purpose: To mechanically loosen and lift dried-on contaminants

Details: Engineered from high-density, open-cell polyurethane foam with a textured surface, Sahara Foam effectively removes gelatin films, oils and dried residues without scratching polished or anodised surfaces. Compatible with deionised (DI) water, isopropyl alcohol (IPA), or approved detergents. Ideal for cleaning gelatin tanks, encapsulation dies, hopper ports, polishing trays, and conveyor belts.

Step 2: Oil Removal with UltraSORB Foam Wipers

Product: UltraSORB Sponge Wipers

Purpose: Absorb large volumes of oils, plasticisers, and loosened residues following initial scrubbing with Sahara Foam

Details: UltraSORB wipers are designed from reticulated polyurethane foam that soaks up heavy oil loads without dripping or smearing. Manufactured to ISO 5 standards and validated for GMP use, they deliver high-capacity uptake in one pass. Ideal for gelatin tanks, oil-lubricated polishing drums, and any equipment surfaces with excess MCT or mineral oil buildup.

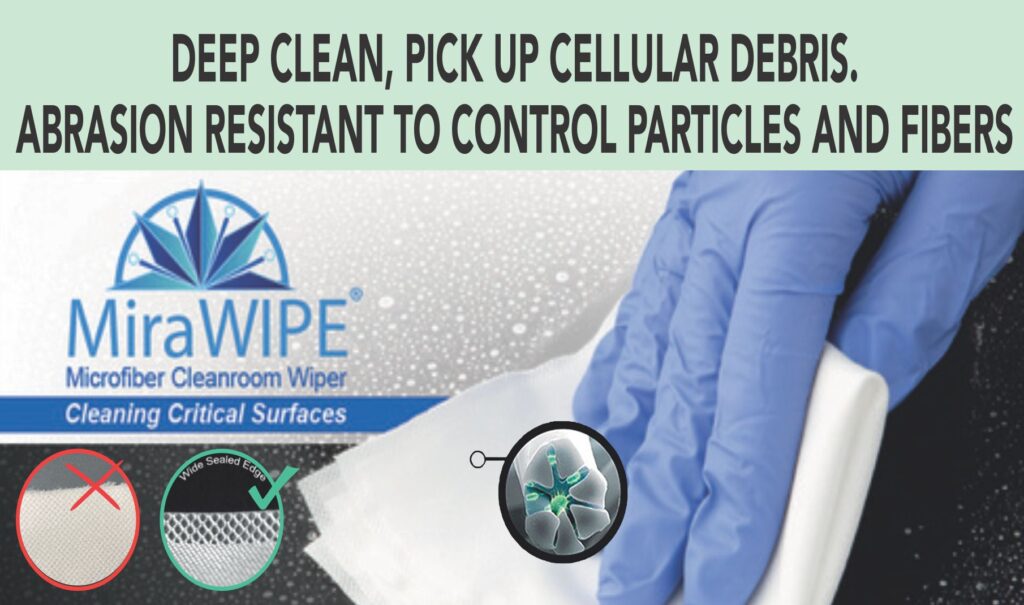

Step 3: Final Wipe-Down with MiraWIPE Wipers

Product: MiraWIPE Cleanroom Wipers

Purpose: Achieve a streak-free, particle-free finish ready for quality assurance (QA) checks or swab validation

Details: Constructed from abrasion resistant, deep cleaning split filament design woven yarn, these wipers provide superior surface contact, entrap submicron particles, and deliver a smooth finish on critical contact surfaces. They are ideally suited for use on fill tanks, encapsulation equipment, spray nozzles, transfer lines and other validated contact areas.

Key Benefits of the Sahara+ System

This advanced cleaning system offers several technical and operational advantages:

- Eliminates abrasive tools: No need for scouring pads, brushes or fiber-shedding cloths

- Time efficiency: Reduces cleaning duration and rework, even in hard-to-access zones

- Validation-ready: Supported by total organic carbon (TOC), particulate, and residue testing data for compliance with cleaning protocols

- Regulatory alignment: Meets Annex 1, FDA, and ISO 14644-1 standards

- Contamination control: Lowers foreign matter risks associated with traditional or reused cleaning materials.

Proven Outcomes for Manufacturers

Adopting the Sahara+ Cleaning System yields tangible results:

- Reduced visual defects from leftover oils

- Quicker elimination of heavy residues

- Pristine, inspection-ready finishes

- Shortened cleaning cycles per batch

- Decreased risk of FM-related production halts

Summing Up

The Sahara+ Cleaning System equips softgel manufacturers with a reliable, GMP-compliant solution to tackle persistent residues without relying on abrasive tools or risking cross-contamination. This system enhances uptime, ensures product quality, and streamlines operations.

Grover Holdings in partnership with Vestilab-Spain, brings this industry leading cleaning solution to softgel producers across India.

To discover how Sahara+ can optimise your operations, contact us at vivek@groverholdings.com or call +91 98211 11623.

Credits: Foamtec International WCC division, Vestilab Spain