In critical fill-finish sterile areas, even the smallest particles and fibers can cause significant contamination issues endangering the finished injectable product for usage, leading to high rejection rates and increased costs.

Choosing the right wipe thus becomes critical to ensure surfaces remain uncontaminated and finished products are not compromised. Which is why, Clean Room wipes should be specifically designed to minimise particle and fiber release while providing efficient and effective cleaning performance.

Why Is It Difficult To Find The Perfect Clean Room Wipe?

When selecting a Clean Room wipe, three key features are typically evaluated:

1. Unit Cost: The cost-effectiveness of the wipe.

2. Efficiency: How well the wipe cleans residues of disinfectants, picks up cellular debris, or lays down adequate disinfectant, depending on its use.

3. Cleanliness: Whether the wipe itself becomes a source of contamination, such as shedding particles or generating fibers due to abrasion.

The ideal Clean Room wipe would encompass all three features. However, the reality is that these features do not simply co-exist in any single wipe.

Let’s explain the above statement using common examples.

Types of Clean Room Wipes:

1. Polycellulose Wipes

- Composition: Blend of polyester and cellulose.

- Characteristics:

- Excellent absorbency.

- Good cleaning performance.

- Cost-effective

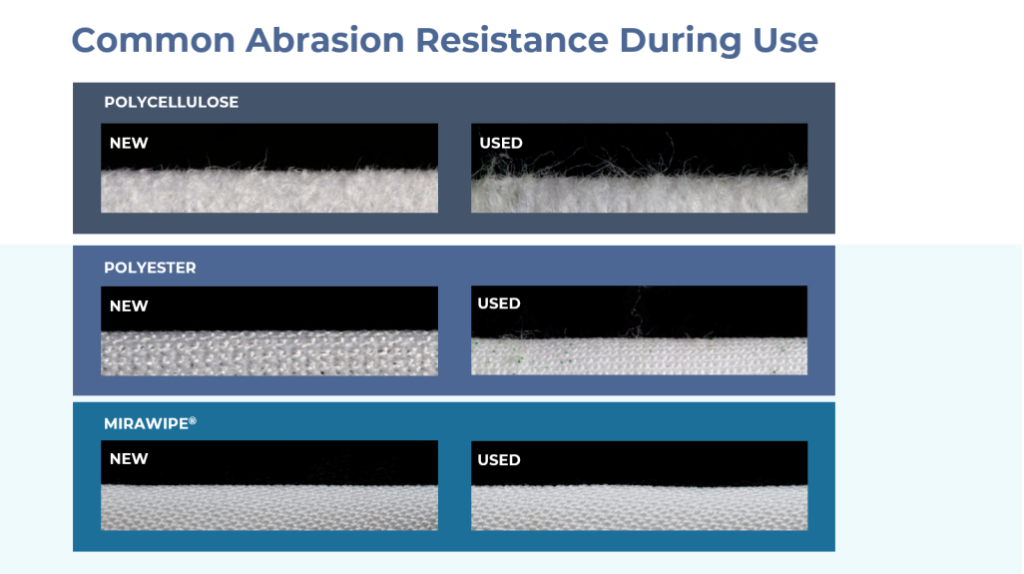

- However, they have poor abrasion resistance and tend to shed fibers and particles – try crushing one in your hand over a dark surface and see the results.

2. Polyester Wipes

- Composition: 100% polyester.

- Characteristics:

- Low-linting and highly absorbent.

- Very clean out-of-the-bag.

- Cost-effective.

- Poor cleaning performance and particle pick-up.

- Tend to snag and release fibers on any protrusions on the surface (try cleaning a filling machine surface or a conveyor).

Both these types of wipes satisfy cost-effectiveness and efficiency but fail to remain clean and integral during use. This is primarily due to the structure of the wipes and also how its edges are sealed.

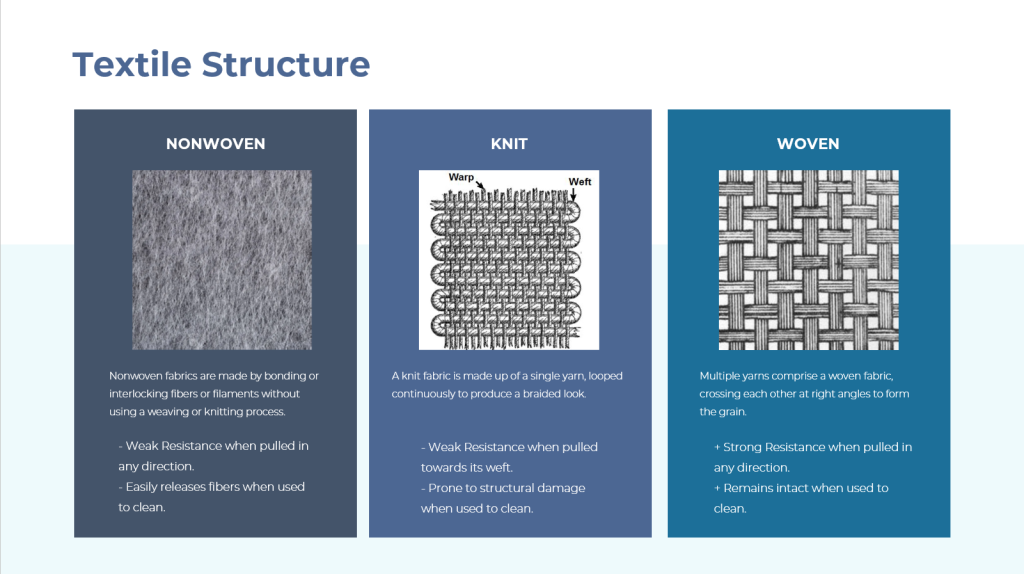

Textile Structures

The structure of the fabric used in Clean Room wipes affects their performance. Here’s how:

- Polycellulose Nonwoven: Made by bonding or interlocking fibers without weaving or knitting. Offers weak resistance when pulled and easily releases fibers.

- Polyester Knit: Made up of a single yarn looped continuously. Offers weak resistance when pulled towards its weft and is prone to structural damage.

Edge Seals

The edges of Clean Room wipes can be finished in different ways to prevent fraying:

- No Seal: Basic cut edges that may fray over time, releasing fibers.

- Heat Seal: Uses heat and pressure to fuse edges, providing better durability than no seal.

How MiraWIPE Scores High and Why Choose MiraWIPE

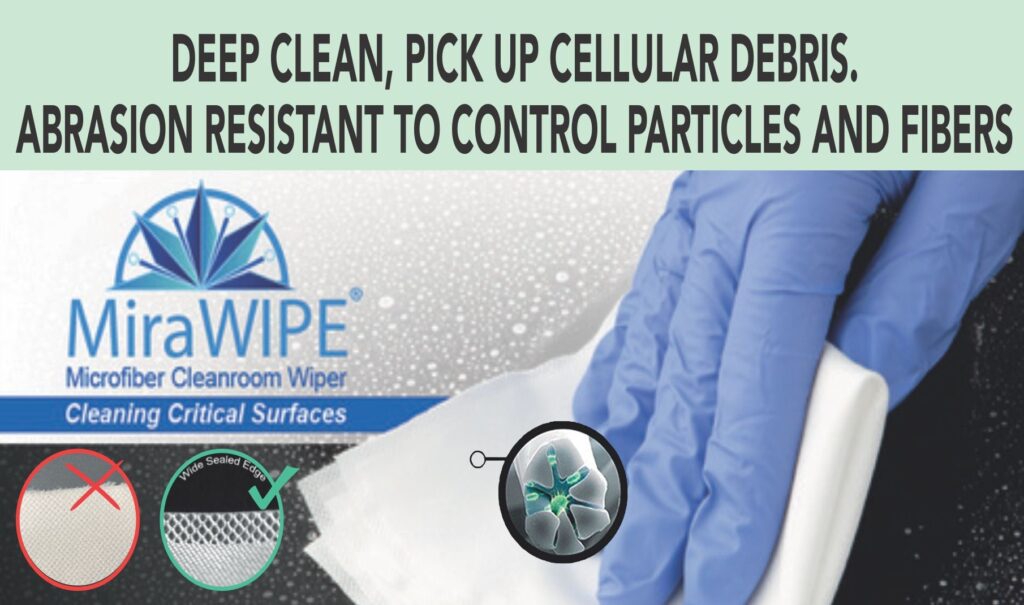

- Composition: Ultra-fine star shaped split filament fibers.

- Characteristics:

- Excellent cleaning performance.

- Very clean out-of-the-bag.

- Highly absorbent.

- Deep cleaning ability to entrap contaminants from the grain of the metal.

- Very high abrasion resistance (does not stretch and snag on surface protrusions and has extremely low fiber release).

- Higher cost compared to polycellulose and polyester wipes.

Textile Structure of MiraWIPE

- Woven: Comprises multiple yarns crossing each other at right angles. Provides strong resistance in any direction and remains intact during cleaning.

Edge Seals of MiraWIPE

- Ultrasonic Seal: Uses high-frequency vibrations to bond fibers, resulting in strong and durable edges.

Why Choose MiraWIPE

- Better Cleaning Performance: Enhanced particle removal and cleaning efficiency. Watch the video to see the difference.

- Better Abrasion Resistance: Engineered to withstand rigorous use. See it in action.

- Better Edge Durability: Ultrasonic seals prevent edge fraying.

- More Surface Area: The threading design offers greater surface area for better contaminant removal.

- Compatible with Common Disinfectants: Ensures effective cleaning with standard disinfectants.

Summing Up

MiraWIPE offers unmatched deep cleaning performance to entrap and remove contaminants, durability to prevent release of fibers even with abrasion, and high absorption to facilitate adequate disinfection. This makes it a great choice for critical areas where fill-finish is done.

MiraWIPE offers great cost savings from minimising rejections and excursions thus more than compensating its higher costs. For more information and samples contact vivek@groverholdings.com or call +91 9821111623.

Credits:

Foamtec International, Wilshire Contamination Control Division

Alsico Iberia S.L., Spain (formerly known as Vestilab CRC S.L.)